PPE World Has Sores Another Game-Changer: Nitrile Coated GlovesNitrile-coated gloves provide a fantastic blend of durability, comfort and dexterity in all kinds of work environments! With the demand for gloves increasing to protect and also reduce infection essentials there is a crucial need even more than ever before of understanding nitrile coatings entirely. Immerse yourself in the universe of these ultimate gloves and experience their renewing take on industry standards that reflect a view towards sustainability.

Its backbone is in the tough build of nitrile coated gloves. Nitrile is free from natural latex proteins, making the material a great option for those that cannot wear traditional latex gloves due to sensitivity. This feature, in particular, is what has brought attention to nitrile gloves - particularly for continued use and growth within medical settings where sensitivity allergens become more critical concern. In addition, nitrile has better chemical and puncture resistance compared to latex or even vinyl gloves, thus more resistant from rips. This toughness result due to not only its material strength, but also because it is slim enough that enables them quick motion over the wrist and great defense too.

This answer is nitrile coated gloves. not only because by far it should have been the accepted glove but also to show us as an industry give a damn about safety and improvements on said process based injuring factors! In an automotive garage, for example nitrile gloves would allow the mechanics to have a better grip on his tools and also keep him safe against any dangerous oils in grease eaten parts he is handling....just as gloves must be water-resistant and tactile sensitive in food processing, to prevent contamination and for quality of product. When your industry goes nitrile over other types of disposable glove it is, at the end of day, clear; grounds will NOT be laid for employee well-being and environmental responsibility to mire between cuts made in performance.

Day to day application of nitrile coated work gloves provides a multitude benefits. Because of its ultimate grip on both wet and oily condition - Thanks to the textured nitrile coating - it makes this glove anti-slip for less slip off incidents which ultimately leads towards an increase in productivity. Secondly and more importantly, the tight fit is fair to have on your hand for a long day out in the field as it will not tire your hands too must - at least less that some other options. Lastly, the gloves are also chemical resistant hence suitable for dealing with cleaning agents solvents and other hazardous substances. The number of replacements is dramatically reduced compared to their disposable adult incontinence products because they will biodegrade over time, whichis another wonderful factor. Taken together, these factors add up to a safer and more productive workplace.

Nitrile coating technology introduced new glove manufacturing processes with sophisticated solutions to the extremely wide scope of distinct applications. One of the fresh innovations in hand protection was a foam nitrile coating that acts as "thousands of tiny squared air pockets," for cushioning to minimize shock and maximize dexterity. This is particularly useful for precision work, or jobs that require a gentle touch. And on the innovation front, micro-roughened nitrile coatings are a game-changer that offers an exceptional grip with good elasticity. These milestones of technology development illustrate that the nitrile substrate is a very versatile one, suitable for many of today's demanding applications put forth by modern industry and issuing new standards in glove performance.

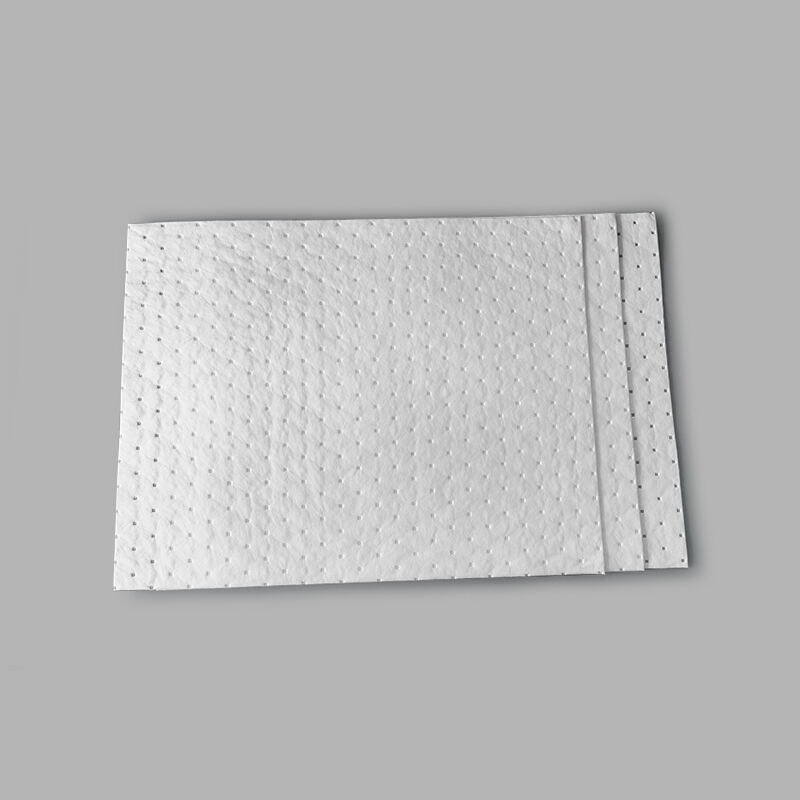

The nitrile coated to controls oil spills are professionals such as soils and natural gas industries ports, the hipping industry, ports, maritime administrations, and engineering contractors. We export to more s100 countries and provides more than 20,000 clients worldwide.

Jiahe has a variety of productions lines that are specifically designed in oil-absorbing materials. The annual production amounts is between 3000 and 5000 tons. nitrile coated and brand technology are the obvious advantages of our company in the chemical and oils absorbent industry.

The company has been awarded IS09001 and nitrile coated. CE, SGS and other certifications, and has more than 20 patents, such as oils spill control products covered through independent intellectuals property rights. Recognized as "Jiangsu Province High-tech Enterprise".

Jiahe's manufacturing centres covers an areas of approximately 20,000 square metres. Jiahe has 16 major products lines and over 200 models to satisfy all the needs of its clients. Jiahe has been nitrile coated, and collaborated with several maritimes safety agencies, Sinopec, PetroChina, and CNOOC.