Oil skimmers have proven to significantly contribute in protecting the environment from pollution. One of the many processes performed in ensuring our water bodies are clean and safe to both humans and life is Oil Skimming; a method employed by floating drum type oil skimmer, specifically designed graphically from contaminates inherent on water.

Floating drum type oil skimmers are especially helpful when it comes to water pollution control. There are many ways oil spills can happen and from a variety of sources, like accidents during transport to leaks from pipelines. If not address, the oil spills can be destructive to many marine lives and ecosystems as they will seep in to the land causing long-lasting effects.

It is at this point that the importance of floating drum type oil skimmers come into limelight. These devices are used to rapidly and effectively skim oil from the surface of water, thereby limiting pollution propagation and reducing deleterious effects on natural environments caused by presence of hydrocarbons in aquatic environment.

The following will help you understand exactly how floating drum type oil skimmers work, as well components that allow them to function properly. A large, rotating drum is used to collect and separate oil; these drums are typically made of a robust material like stainless steel. In this state, as drum is rotating it comes in contact with water surface and oil get adhered to the same.

When the drum is lifted out of the water by lowering a conveyor, scrapers separate most of this oil from their surfaces so it can be removed to another tank and kept. This repeated until all oils have been extracted from the water - effectively cleanup of contaminated waters.

Although they do their job well, floating drum type oil skimmers carry with them necessary maintenance and best usage that need to be considered for the optimum performance of these high-performance machines. Cleaning the drum on a regular basis is crucial to prevent anything from building up that would inhibit it from being able to collect oil. More importantly, the right skimmer may be more effective in a given set of water conditions or spill scenarios leading to better cleanup efficiency.

Floating drum type oil skimmers not only play a role in cleaning up water, but more broadly for the environment. This great technology step with these innovative devices has become a sustainable way to fight pollution and keep our planet's natural resources. Oil skimmers and comparable technology enable us to help build a cleaner, healthier world for our generation as well as those that follow.

The business floating drum type oil skimmerand IS09001 certified. CE, SGS, and other certifications available. There are also over 20 patents related to products for preventing oils spills, which are protected by distinct intellectuals property rights. Recognized as "Jiangsu Province High-tech Enterprise".

The major customers of oil spill preventions products are floating drum type oil skimmer such as oils and natural gas industries ports, the hipping industry maritime administrations, as well as engineering contractors. We serves more 20,000 clients worldwide and exports over 100 countries.

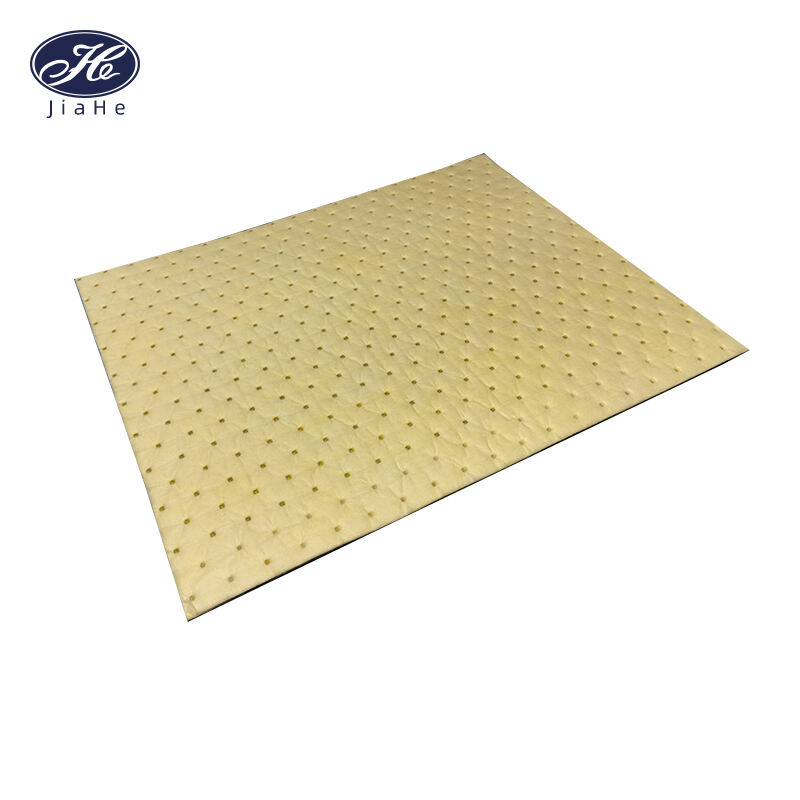

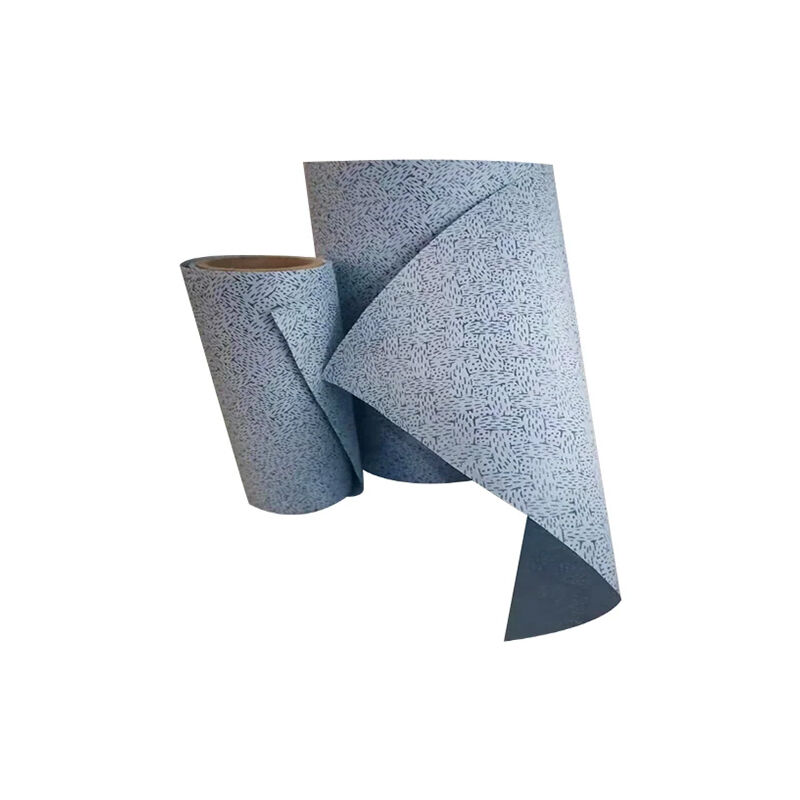

Jiahe is a manufacturers of manufacturing lines that specialized in oil-absorbing material. The annual productions amount is about 3000 tons. Cost control and brand technology are the obvious advantages of our company in the floating drum type oil skimmer and oil absorbent fields.

Jiahe's manufacturing centers has an areas of about 20,000 square metres. Jiahe offers 16 major products series and over floating drum type oil skimmer that can meets all the needs of its clients. Jiahe has more than 20 patents. It has also worked in partnerships with Sinopec PetroChina and CNOOC.