On building sites silt is about the same as mud, which an intermediate grade of dust or soil. They are pollutants that get carried in rainwater or flowing water, which harms the environment. This is where these silt control barriers are implemented to avoid or stop it from spread and damaging. These barriers are made of fabric, geotextile and gravel. For the function of an ecosystem, it is important for them to be present. But they have some particular moves to work precisely.

Their location on the other hand is one of the things that make silt control barriers more efficient. It is done that flow only but silt pass not in so doing many much like this silently blocks passes. The other key is to ensure The platforms are absolutely rock solid so that when they hit the ground after being wrenched into shape at max effort 1, it unloads perfectly faithfully because its not getng to bend or break and cost you a penalty of shame.

Other essential strategy of curb maintenance Proper maintenance will keep your barriers in a functional condition and it also permits you to function as estimated. The accordion barriers were also checked for wear and tear, replacing those that have been damage or worn-out. This is why taking the time to dig or haul out all of that silt or other fill material and dispose it behind your training walls in a catchpit really pays off by ensuring they remain at an ideal functionality.

ADVANTAGES OF silT CONTROL BARRIERS FOR USE ON CONSTRUCTION SITES

Benefits Of Silt Control Barriers To You There are like a trillion benefits that you will be able to get when it comes silt control barriers. One of such advantages is achieved using them at construction sites Well there are many functions, one of which obviously is silt Which if it went into our waterways would hurt [the resource] and the wildlife.

Saving Not only do good silt control barriers help keep our air clean, they also save money. No more scheduling unnecessary, expensive maintenance on landfill projects for prevention against erosion and rubbish.

It also deploys silt control barriers to make hays while complying with the regulations. Many regions already mandate their use on construction sites. Builders can avoid the risks of lawsuits and fines by adhering to these types of laws.

In order to optimize the of silt management barriers, it should be used in them. The installation should be the right type(width of cuts or selection as per ease), at perfect arrangement(or order) according to terrain.

If you are not inspecting the barriers on a regular basis for damage, wear and failure than these issues will go unnoticed. When problems arise they need to be addressed quickly and with minimal environmental damage.

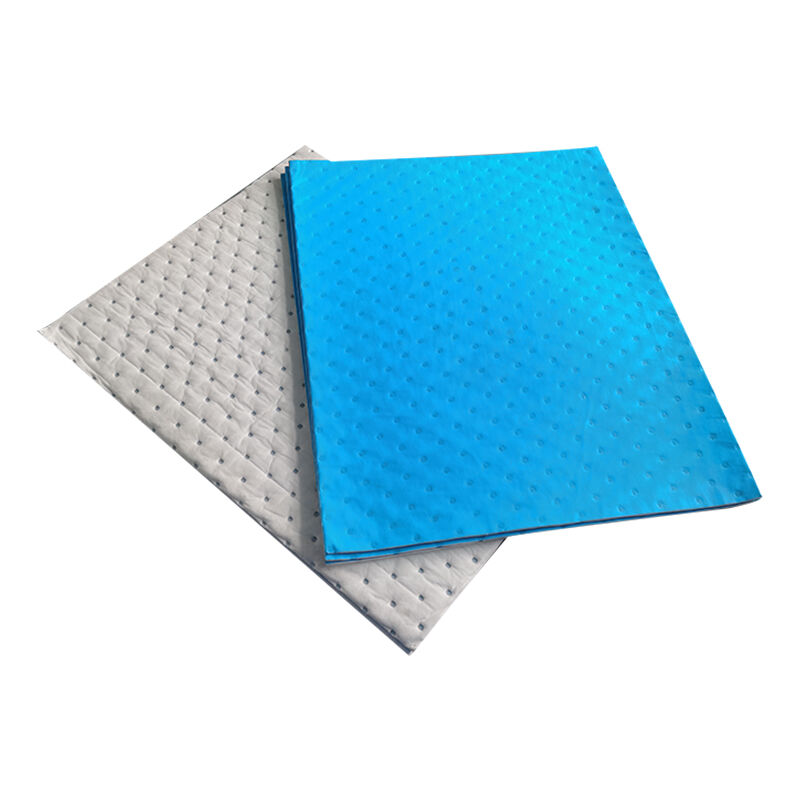

Biodegradable materials are used to make silt control barriers and geotextiles thus enabling earth- (as opposed disposable) friendly variants of these erosion protection interventions as well. That is good news for the world because it decomposes after a few years with no ill effects.

These barriers are constructed from organic materials such as jute, coir and straw. Well you can do your part environmentally-wise and really make this one of the greenest options by selecting bags that are made from natural materials so we can be friends with the environment once again!

Well, there is nothing of great importance than this at the time when Installation and maintenance work for Silt Control Barriers.

5 Tips When Installing and Maintaining Any Silt Control Barrier In The Ground

Make a barrier in the right places, that will slow silt and cleanse wash water.

Be sure to position the barrier securely so it is not at risk of collapsing or shifting.

Throw discarded barriers in garbage properly so as to avoid polluting environment.

In a word, the silt fence should be in construction environment protection done. Ways in which builders should follow to improve this value: Properly installation and maintenance of silt control barriers.

The company has been awarded IS09001 and silt control barriers. CE, SGS and other certifications, and has more than 20 patents, such as oils spill control products covered through independent intellectuals property rights. Recognized as "Jiangsu Province High-tech Enterprise".

Jiahe has a manufacturing facility covering an areas of 22,000 square meters. Jiahe is homes to 16 major series as well as more than 200 different models of products that can meet the different demands of customers. Jiahe has obtained more than 20 patents and cooperated with multiple maritimes safety bureaus, silt control barriers, PetroChina, and CNOOC.

The silt control barriers to controls oil spills are professionals such as soils and natural gas industries ports, the hipping industry, ports, maritime administrations, and engineering contractors. We export to more s100 countries and provides more than 20,000 clients worldwide.

Jiahe has a variety of productions lines that are silt control barriers. The annuals production is approximately 3000 tonnes. Brand technology and costs control are the main advantages we have in the oils and chemical absorbent industry.